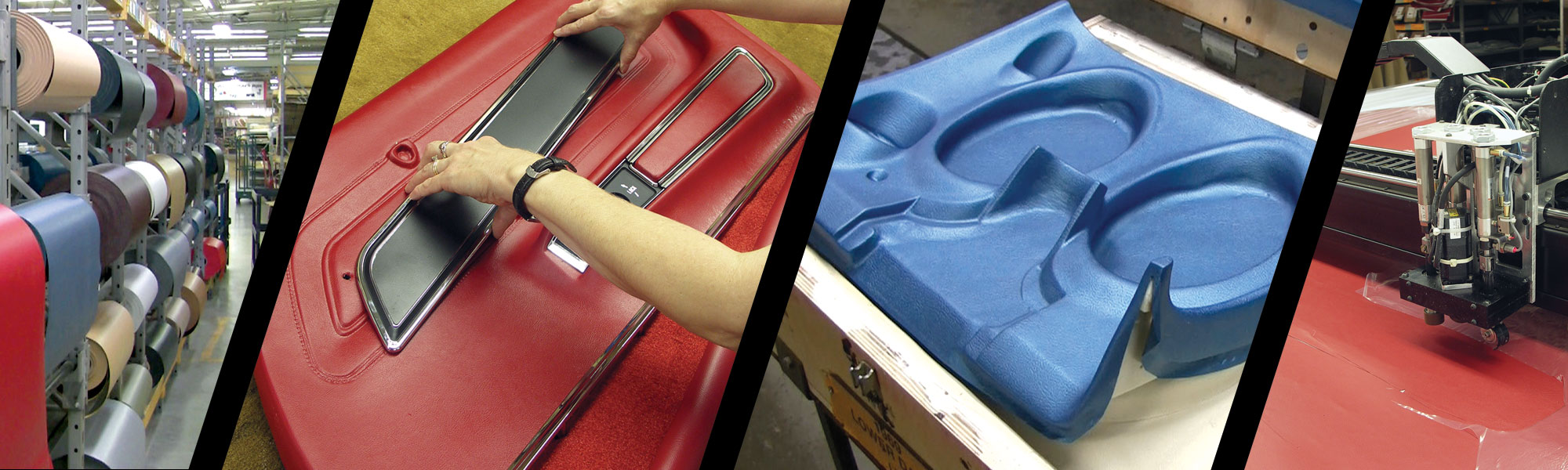

Auto Accessories of America has manufactured and distributed the highest quality parts, interiors and accessories for the automotive aftermarket since 1977. We have been making door panels, dash pads, seat covers, seat backs, and various other interior trim items since 1985.

Our large central Pennsylvania manufacturing facility provides plenty of space for modern equipment and raw materials, which means higher production and faster turnaround times for you. But offering quality products at competitive prices has always been our top priority.

Auto Accessories of America uses a combination of high tech processes and hand crafted detail for many of its applications.

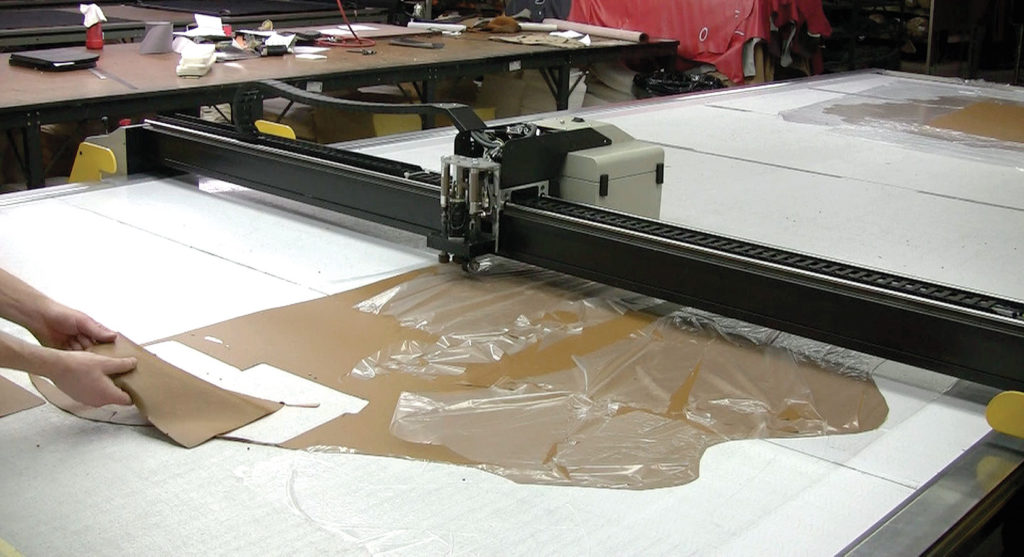

- Cut & Sew — Gerber cutting machine and Sewing machines

- Digitizing table to quickly pattern from original parts or samples

- Multiple digital cutting machines

- Multiple material capability including leather, vinyl, pressboard, corrugated, carpet, foam and film

- Skiving, overlock, double needle and single needle machines

- Team of skilled craftspeople

- Utilize multiple 5-axis CNC routers

- Large format CNC sewing for pleats and custom patterns

- CAD capable for modeling and toolpath generation

- Machining and trimming

Dies — Clicker Press

- An 88 ton programmable press

- Features multiple material capabilities including leather, vinyl, pressboard, carpet, foam and films

- Steel rule and forged dies

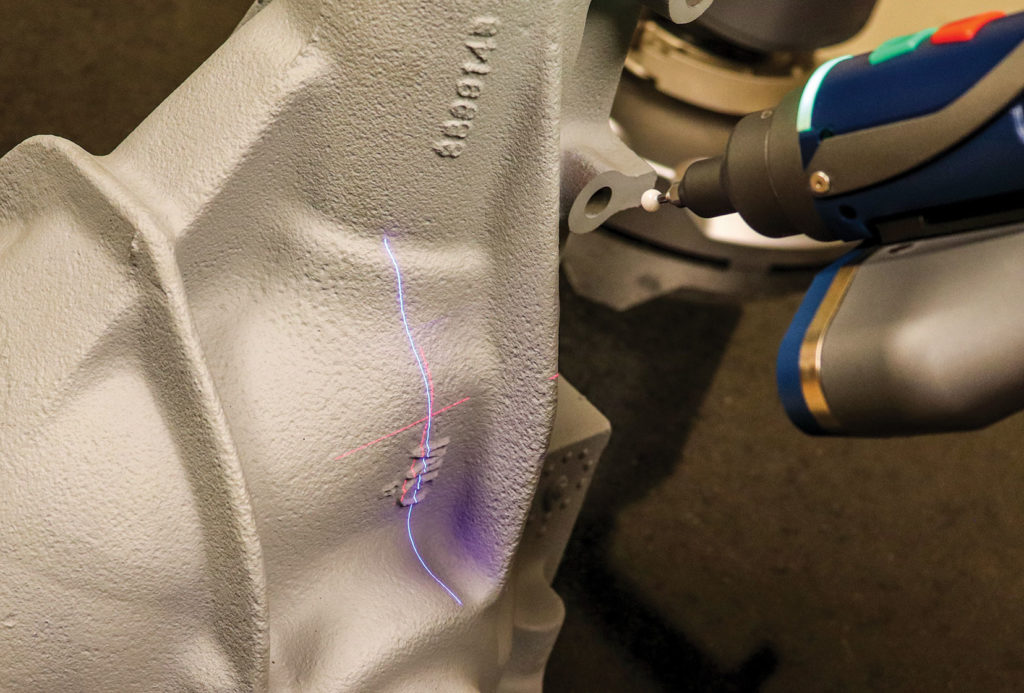

- 3D Laser Scanner with physical probing capability

- Accurately recreates OE parts for reverse-engineering

- Allows for high-precision quality checks of critical parts

- Full suite of 2D/3D modeling and digitizing software

- CAM software for creating molds utilizing 5-axis CNC routers

- Large 25 x 14 downdraft paint booth with curing cycle, mix room and prep room

- Over 100 interior colors in stock

- Custom color matching ability

- HVLP spray guns and equipment

Refurbishing

- Media blasting

- Parts washing

- Welding

- Painting

- Thin and thick gauge material compatible

- In-house tool capabilities

- Composite tooling available for low volume production

- Wide range and large inventory of materials

- Urethane foam products

- Metered dispensing equipment

- Seating and cushioned interior components

- In-house tooling capabilities

- Composite tooling available for low volume production